Compaction technology can have a significant impact on your bottom line. Utilising technology can help you eliminate passes and deliver substantial savings in labor, fuel and machine wear. The technology also can ensure compaction goals have been achieved, eliminating the need for costly re-work at the jobsite.

THE TRIPLE-SHAFT EXCITER SYSTEM

The patented Ammann triple-shaft exciter system provides industry-leading climbing ability and compaction output. It ultimately delivers outstanding results, even on cohesive soils.

The triple-shaft exciter system eliminates erratic movements, allowing smooth travel even through heavy, cohesive soil. The unique system’s consistent movement enables effortless climbing over obstacles or while compacting backfill materials with high moisture content. This is done without the usual suction effect, which can leave plates at a standstill.

The ease in handling and manoeuvering of the plate is particularly helpful when the use of low frequency/high amplitude is required.

INTELLIGENT COMPACTION

ACE is a proprietary compaction system from Ammann that provides accurate, real-time data to operators.

Precise, transparent and verifiable compaction processes increasingly are required on construction sites. Ammann took the first steps toward providing these processes in 1998 with the advent of Ammann Compaction Expert (ACE), an automated compaction measurement and control system.

ACE has been continually improved since its introduction and remains the industry leader. It is the only system that automatically adjusts amplitude and frequency based on ground characteristics.

The benefits of ACE technology are significant. Among them:

- It can reduce the number of passes a roller makes and deliver savings on fuel, labor and machine wear.

- ACE helps ensure proper compaction is achieved and prevents costly rework, which in some cases can even require a return to the jobsite.

- It extends the life of the compacted material – and structures placed on top of it – by providing a homogenous surface without weak spots.

ACE technology is available for both soil and asphalt applications. There are three ACE options available.

ACE

For use with vibratory plates and trench rollers

- Relative compaction measuring device

- Continuous information about compaction levels

- Evaluates when maximum compaction has been reached

- Continuously measures compaction progress and communicates that information to the operator via an LED display on top of the machine

ACEforce

For use with single-drum rollers, light and heavy asphalt rollers

- Provides measurement and documentation

- Precisely measures and evaluates material stiffness

- Operator guiding function shows compaction progress

- Includes ADS documentation software with office analyzing feature

- Can utilise all major manufacturers’ GPS products to provide mapping and operator guidance

ACEpro

For use with single-drum and heavy asphalt rollers

- Provides compaction measurement, automatic control and a documentation system

- Precisely measures and evaluates material stiffness

- Continuously adjusts frequency and amplitude depending on compaction measurements

- Delivers the highest compaction efficiency by sending optimal force into the ground

- Eliminates drum jumping and therefore minimizes the risk of over-compaction or material destruction

- Includes ADS documentation software with office analyzing feature

- Can utilise all major manufacturers’ GPS products to provide mapping and operator guidance

- Intuitive system operation and adjustments fully integrated in machine main display

“WHAT IS ADS?“

Ammann Documentation System

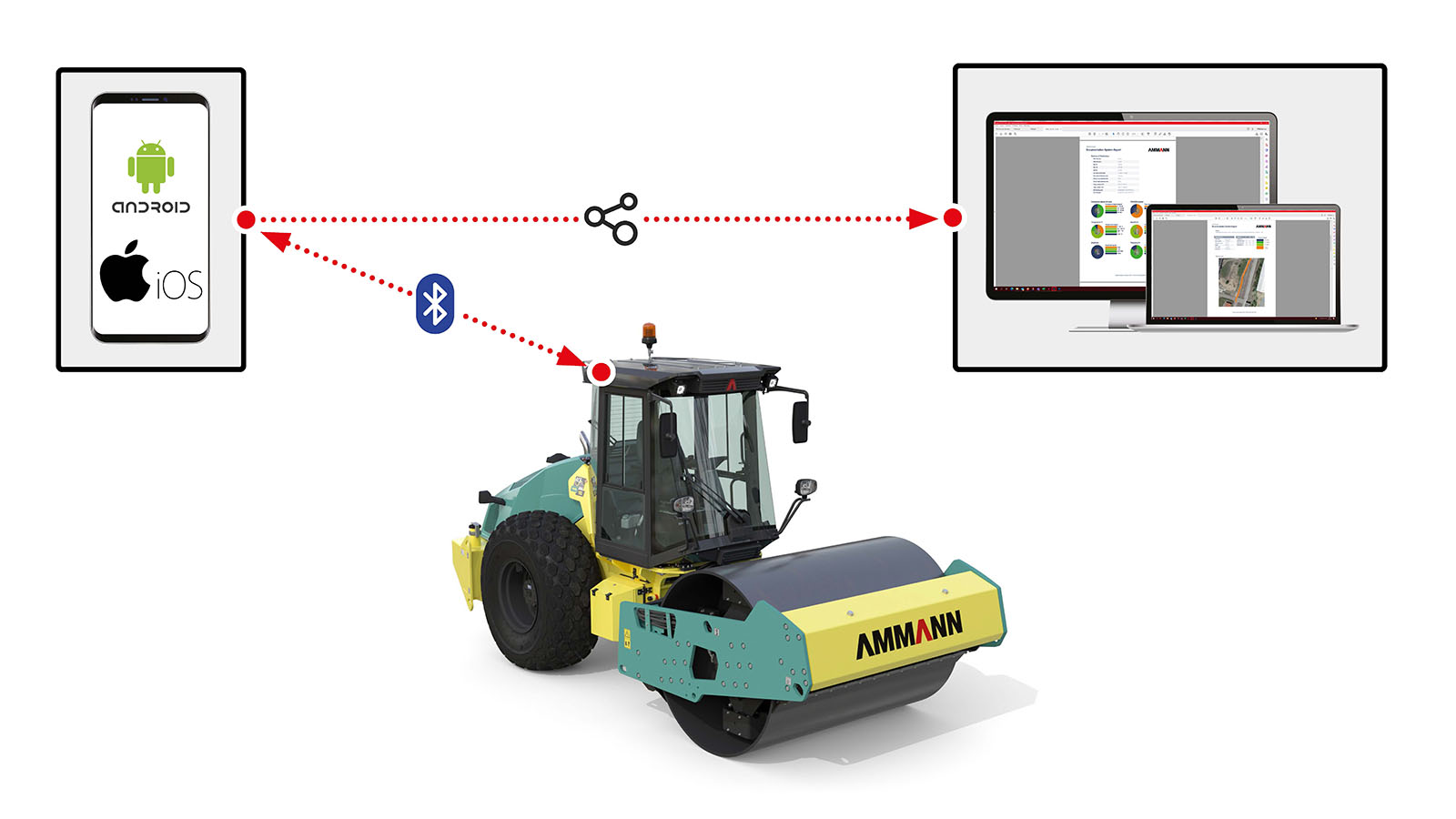

ADS enables documentation of jobsite compaction results measured by ACEforce or ACEpro systems. It is installed on Ammann heavy compactors and utilises GPS positioning for precise location.

- Precise jobsite documentation

- Easy quality control

- Increased efficiency (time and fuel economy, reduce re-work costs, extend life, CO2 reduction)

- No risk of damaged, stolen or lost Android/iOS device during recording

GPS-BASED COMPACTION

ACEplus combines the ACE (Ammann Compaction Expert) measurement and control system with a navigation system. It provides an efficient analysis and documentation system for continuous compaction control (CCC).

The satellite navigation system accurately assigns the measured compaction values to the position coordinates and the time. The graphic display of measurement data relays the on-site compaction work and enables a fast and reliable performance analysis.

ACEplus therefore increases process reliability and integrates quality control measures in the work process.

With Q Compaction, you can supplement the technologies of the Ammann rollers with a GPS-based, position-accurate digital area compaction control. The compaction information is automatically recorded, visualised for the driver with positional accuracy and stored in a data cloud. In this way, all roller drivers on a construction site are informed about the compaction status. This increases the quality and at the same time reduces the rolling time.

OSCILLATION

Oscillation eliminates about 90 per cent of the stress on materials when compared with a traditional circular vibratory system. This is important when compacting on bridges, over sewers and utility lines and near buildings where a traditional vibratory approach can cause damage.

Oscillation uses less force but delivers both vertical and horizontal energy, essentially massaging the aggregates into place. The drums maintain constant contact with the ground and deliver both static and dynamic forces.

Compactors with oscillation can bring substantial benefits to jobsites. In asphalt applications, they are able to work on hot mats sooner than traditional rollers, and they are able to stay on cold mats longer, too. This greatly expands the compaction window, essential for time-pressed crews.

The rollers also are great fits for sealing asphalt joints. The massaging motion of oscillation provides enough energy to break down the hot asphalt – yet does not damage the adjacent cold mat.

When working in soil applications, the compactors prevent damage to sensitive structures and over-compaction.