-

Photos

-

Videos

This paver utilises a technologically advanced paver control system that features a variety of automated functions. The system enables productivity, quality and cost-saving efficiency. The AFT 400-3 is productive when space is open, but can negotiate curves and tighter spaces, too. The tracks provide grip, particularly helpful on steep grades. The material feeding system provides consistent mix flow.

APPLICATIONS

- National roads

- Municipal roads

- Building lots

- Squares and courtyards

- Sporting courts

-

Highlights

-

Specifications

HIGHLIGHTS

- Deutz Stage IIIA (T3) and Stage V (T4f) engines available for all models

- Advanced PLC system

- Vibrating or tamping / vibrating screeds

- Electric- or gas-heating screeds

- Capacity of 350 tonnes per hour

- Minimum paving width of 0.7 metres

- Maximum paving width of 4.7 metres

- Proportional sensors for auger speed control

- Constant feedback on all paving parameters from PaveManager 2.0

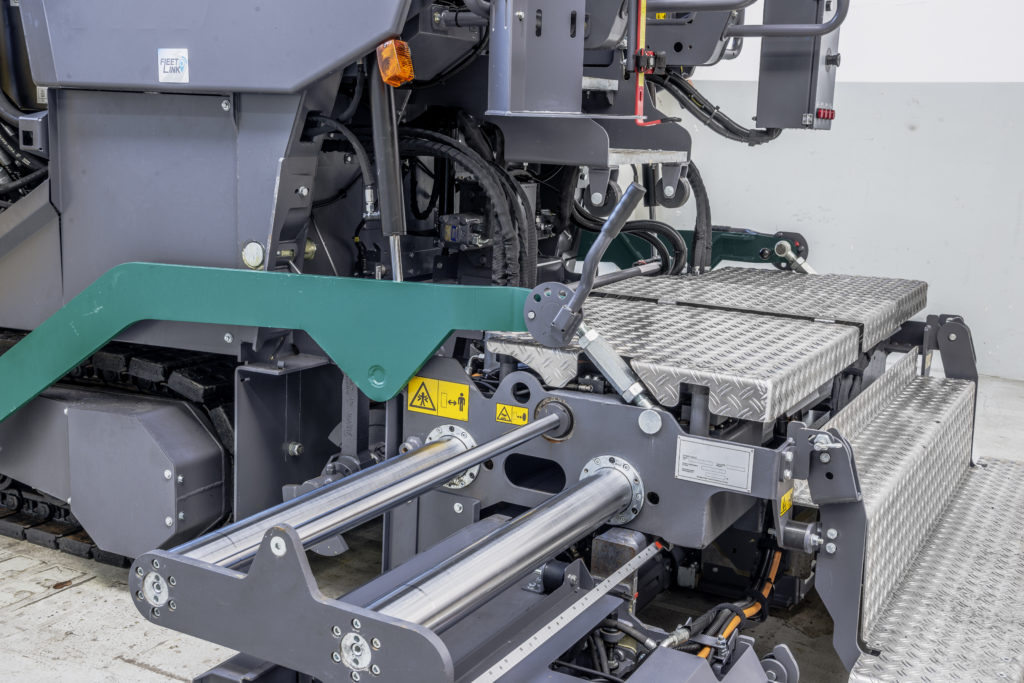

MATERIAL FEEDING SYSTEM

|

Material Conveyor

An efficient conveyor system ensures material flows consistently from the hopper, so productivity and quality goals can be achieved.

|

|

Auger System

Consistent auger distribution of material across the screed is essential to placing a quality mat with minimal segregation.

|

|

The Hopper The hopper is designed to reduce spilling during connections between the paver and the lorries. It is also designed to maximise flow and minimise segregation. The result: improved quality in the form of smoother mats. An optional hydraulical front flap reduces spilling and improves the emptying process, ultimately resulting in less manual work.

|

|

SAFE Impact system Ammann Premium Tracked Pavers offer the Safe Impact System – a hydraulic anti-shock push roller that avoids surface marks caused by truck docking. The system also extends docking length, providing flexibility to work with varied truck models. |

|

Truck Assist (optional) This system improves the communication between the paver and the truck driver. It also minimises bumps and spills that can negatively impact paving quality.

|

| Set Assist (optional) This intelligent system saves the position of the auger and the screed before relocating the paver.

|

Operator Platform

|

PaveManager 2.0 The automated paving system constantly monitors the process and provides feedback to operators. It also controls many key functions for precise results.

|

|

Operator Platform A comfortable work environment is also a safe and productive work environment, too. The City Paver operator platform optimises visibility and ensures all key controls are easily accessible. The operating system is nearly identical to those of other Ammann pavers, making it easy and safe for operators to switch between models.

|

Engine, undercarriage key components

|

Engines Deutz engines are the power behind the Ammann AFT 400-2, AFW 400-2, AFT 400-3 and AFW 400-3 Asphalt Pavers. Highly advanced e-hydraulic controls provide efficiency. The engines are available to meet Stage IIIA or Stage V standards.

Stage IIIA / T3 Engine

Stage V / T4f Engine

|

|

Track System Tracks with high pulling forces help Ammann City Pavers overcome the varied terrain that often is encountered in cities. The pavers provide manoeuvrability, too.

|

Screeds

|

The SV and STV3500 Screeds

|

Gas or electric heating

|

|

Highest paving quality

|

|

|

Eccentric Flexilever

|

|

Simple side shield control

|

| AFT 400-3 TRACKED ASPHALT PAVER – CITY CLASS, PREMIUM | |

|---|---|

| WEIGHT & DIMENSIONS | |

| WEIGHT (INCLUDING STANDARD SCREED) | 10 500 kg |

| A = MACHINE LENGTH | 5022 mm |

| B = TRANSPORT LENGTH | 4990 mm |

| C = TRACK LENGTH | 2090 mm |

| D = HOPPER LENGTH | 1990 mm |

| E = MACHINE HEIGHT | 3600 mm |

| F = TRANSPORT HEIGHT | 2920 mm |

| G = HEIGHT (W.O. CANOPY) | 2400 mm |

| H = MATERIAL LOADING HEIGHT | 500 mm |

| I = MACHINE, OPEN HOPPERS WIDTH | 3150 mm |

| J = TRANSPORT WIDTH | 1800 mm |

| K = TRACK GAUGE WIDTH | 1200 mm |

| L = MAX. APPROACH ANGLE | 13° |

| CAPACITY & PERFORMANCE | |

| PLACEMENT THICKNESS (MAX.) | 200 mm |

| THEORETICAL PAVING CAPACITY | 350 t/h |

| PAVING SPEED (MAX.) | 25 m/min |

| TRANSPORT SPEED (MAX.) | 4 km/h |

| CRAWLER | |

| CRAWLER LENGTH (AXLE TRACK) | 2090 mm |

| CRAWLER WIDTH (PADS) | 260 mm |

| FINAL DRIVE | Hydrostatic |

| MATERIAL FEEDING SYSTEM | |

| HOPPER CAPACITY | 10.5 t |

| HOPPER DUMPING HEIGHT CENTER (W. HOPPER FLAP) | 500 mm |

| HOPPER WIDTH, INTERNAL | 3040 mm |

| CONVEYOR TYPE | Dual bar feeder, reversible and independent |

| CONVEYOR WIDTH | 700 mm |

| CONVEYOR CONTROL | Aut. / Proportional paddles |

| AUGER DIAMETER | 320 mm |

| AUGER CONTROL | Aut. / Ultrasonic sensors |

| AUGER HEIGHT ADJUSTMENT | 200 mm (hydraulic) |

| ENGINE | |

| ENGINE MODEL | Deutz TD 2.9 L4 |

| RATED POWER @ 2200 RPM | |

| EU Stage V / U.S. EPA Tier 4f | 55.4 kW |

| EU Stage IIIA / U.S. EPA Tier 3 | 54 kW |

| ELECTRICAL SYSTEM | 24 V |

| FUEL TANK CAPACITY | 73 l |

| OPERATOR STATION | |

| OPERATOR CONSOLE | Slidable and tiltable control panel |

| DASHBOARD | Pave Manager 2.0 (PLC) |

| PLATFORM | Sliding stations with pivotable seats |

| ROOF | Canopy with lights (optional) |

| SCREED OPTIONS | ||||

|---|---|---|---|---|

| SV 3500 G | SV 3500 E | STV 3500 G | STV 3500 E | |

| BASIC WIDTH | 1.75 m | 1.75 m | 1.75 m | 1.75 m |

| HYDRAULIC EXTENDED WIDTH | 3.50 m | 3.50 m | 3.50 m | 3.50 m |

| MAX. WORKING WIDTH | 4.70 m | 4.70 m | 4.70 m | 4.70 m |

| HEATING SYSTEM | Gas (LPG) | Electric | Gas (LPG) | Electric |

| CROWN RANGE | -2.5% to +4.5% | -2.5% to +4.5% | -2.5% to +4.5% | -2.5% to +4.5% |

| SCREED TYPE | Vibration screed | Vibration screed | Tamper & vibration screed | Tamper & vibration screed |